|

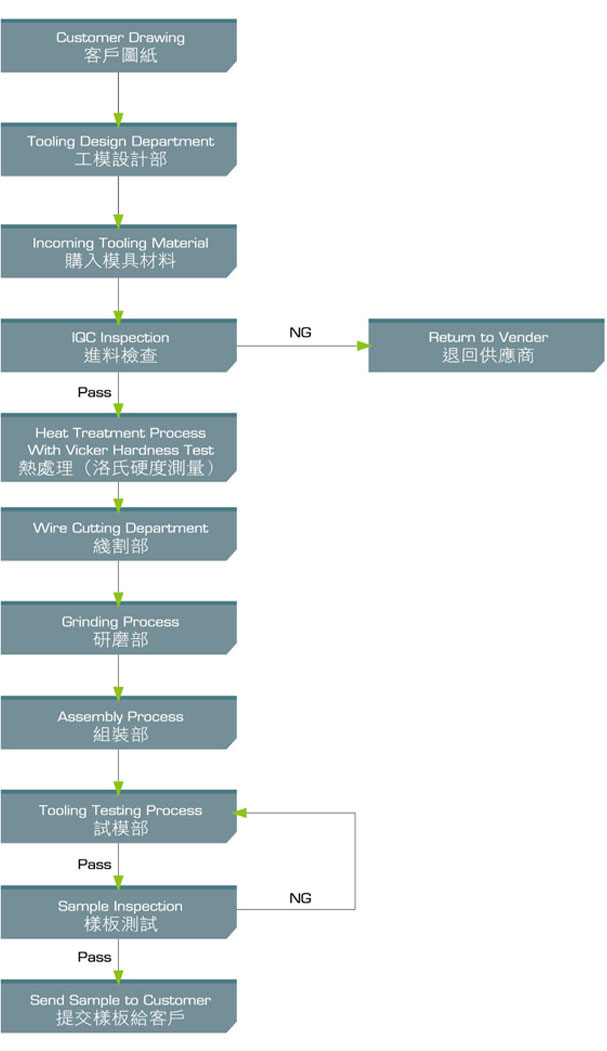

Design & Tooling Department

Precisions of Molds are the prerequisite of quality products and invaluable

assets to our customer and company. Process starting from designing stage,

to wire-cut and assembly process will be made in-house with our professional

engineers and technicians who have substantial experience in metal stamping

industry. Additionally, all mold materials and designs will be strictly

based on characteristics and requirement of customers' products.

By having a direct control of our tooling department and providing constant

service of molds at our warehouse department, we are committed to make

precise molds with long lasting life-time in order to ensure high quality

products.

Materials used for Mold:

** D2 , SKD 11, XW-41, ASP 23 Origin: Daido (Japan), Assab (Sweden)

|